INDUSTRIE

Medical technology

In medical technology, hardening plays a crucial role in ensuring the precision, durability and safety of medical devices and instruments.

Medical technology

at a glance

Dental technology

Hardened components from HTR reliably fulfil the particularly high requirements for their use in dental technology.

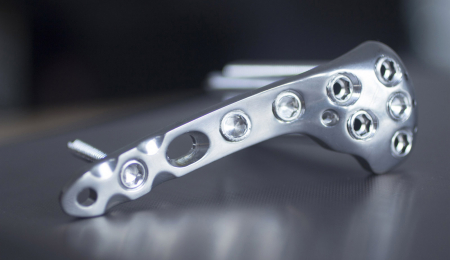

Implants

HTR hardens wear-resistant components for plastics recycling machines that are used around the world.

Surgical tools

HTR refines medical tools such as bone cutters and bone rasps for use in hospitals and doctors' surgeries.

Get a quote

Request a free and non-binding

an offer from us now!

Why hardening in medical technology?

- Resistance of materials: Medical devices often have to withstand high stresses, whether through use in the body or through repeated cleaning and sterilisation processes. Hardening processes can improve the strength and durability of the materials used, which increases the service life and reliability of the devices.

- Wear resistance: In many medical technology applications, devices are exposed to heavy wear, whether due to friction, abrasive particles or chemical effects. Hardening processes can be used to make materials more resistant to wear, which improves their performance and safety.

- Biocompatibility: Materials used in medical devices often have to be biocompatible, i.e. they must not have any harmful effects on the human body. Some hardening processes, such as plasma nitriding, can improve the surface properties of materials without compromising their biocompatibility.

- Corrosion resistance: Hardening processes can increase the corrosion resistance of materials, which is particularly important when medical devices come into contact with body fluids.

- Hygiene and sterilisation: Hygiene is of crucial importance in medicine. Hardening processes can improve the surface quality of materials, making them easier to clean and sterilise. This helps to reduce the risk of infection.

- Precision and functionality: Some medical devices require high-precision components that must have certain mechanical properties. Hardening processes can help to manufacture these components to the exact specifications required and optimise their functionality.

- Standardisation and quality assurance: They enable the standardisation of material properties and manufacturing processes, leading to improved quality assurance in the manufacture of medical devices.

- Safety and reliability: By improving material strength, wear resistance and functionality, hardening processes help to increase the safety and reliability of medical devices, which in turn ensures patient safety.