INDUSTRY

Toolmaking & mechanical engineering

In toolmaking and mechanical engineering, hardening is a critical step in improving the service life and performance of tools, moulds and other components.

Toolmaking and mechanical engineering

at a glance

Environmental technology

HTR hardens wear-resistant components for plastics recycling machines used around the globe.

Punching and forming technology

HTR uses the proven vacuum hardening process to refine tool components that are essential for stamping and bending.

Mould making

During hardening, HTR gives metal moulds precisely defined properties that make them particularly robust and wear-resistant for use in mould and tool making.

Environmental technology

HTR hardens wear-resistant components for plastics recycling machines used around the globe.

Get a quote

Request a free and non-binding offer from us now!

REFERENCE

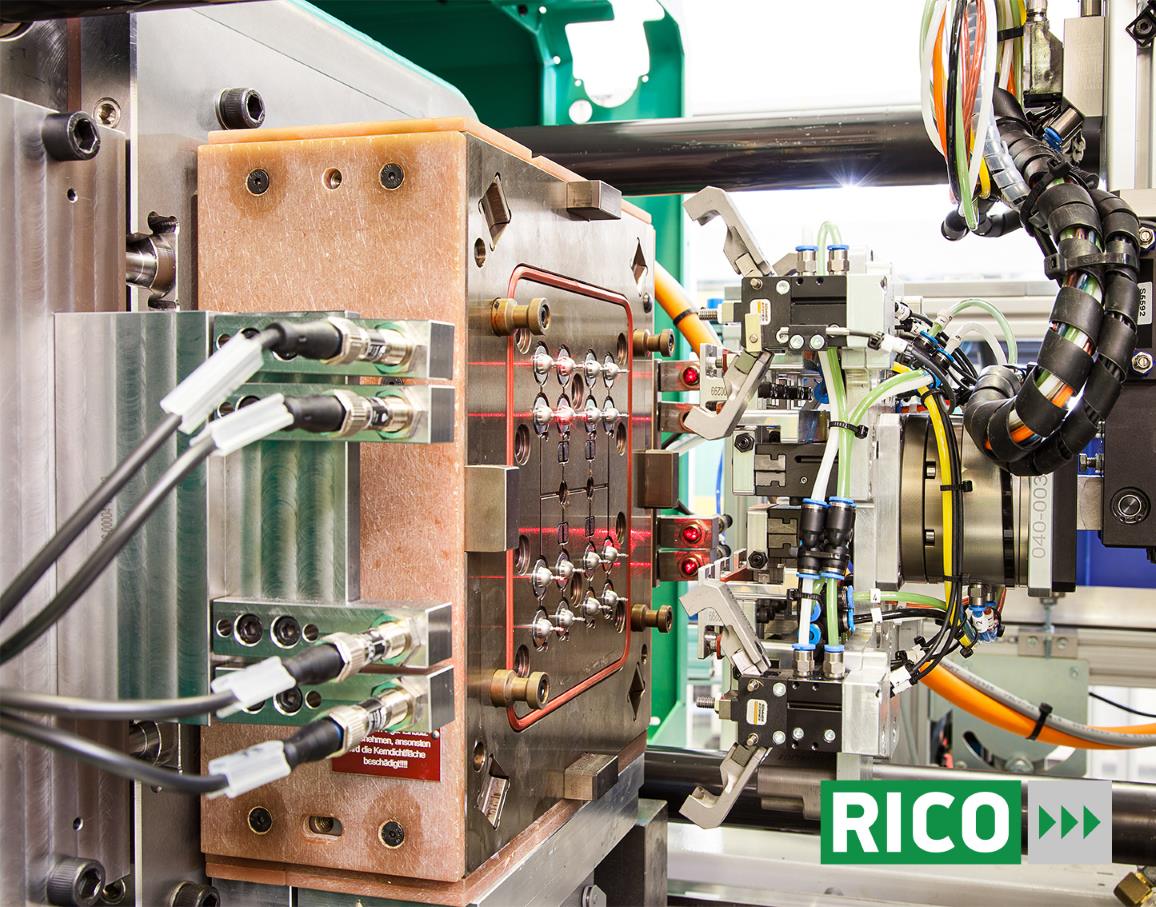

RICO Elastomere Projecting GmbH

Hardened components for mould making

HTR hardens injection moulds for RICO GmbH, which are used in the production of plastic components for the household appliance, medical technology and automotive industries.