TOOLMAKING & MECHANICAL ENGINEERING

Environmental technology

HTR hardens wear-resistant components for plastics recycling machines that are used around the world.

Further topics from toolmaking & mechanical engineering:

Stamping and forming technology | mold making | processing machines

Environmental engineering refers to the technical and technological processes used to protect the environment and restore damaged ecosystems.

Plastic recycling machines and system components

An important field of activity in environmental technology is waste disposal, which also includes the recycling of waste. The Upper Austrian Erema Group is the number one in the development and production of plastic recycling machines and system components. HTR has been refining components such as extruder screws and screens for the company since 2001.

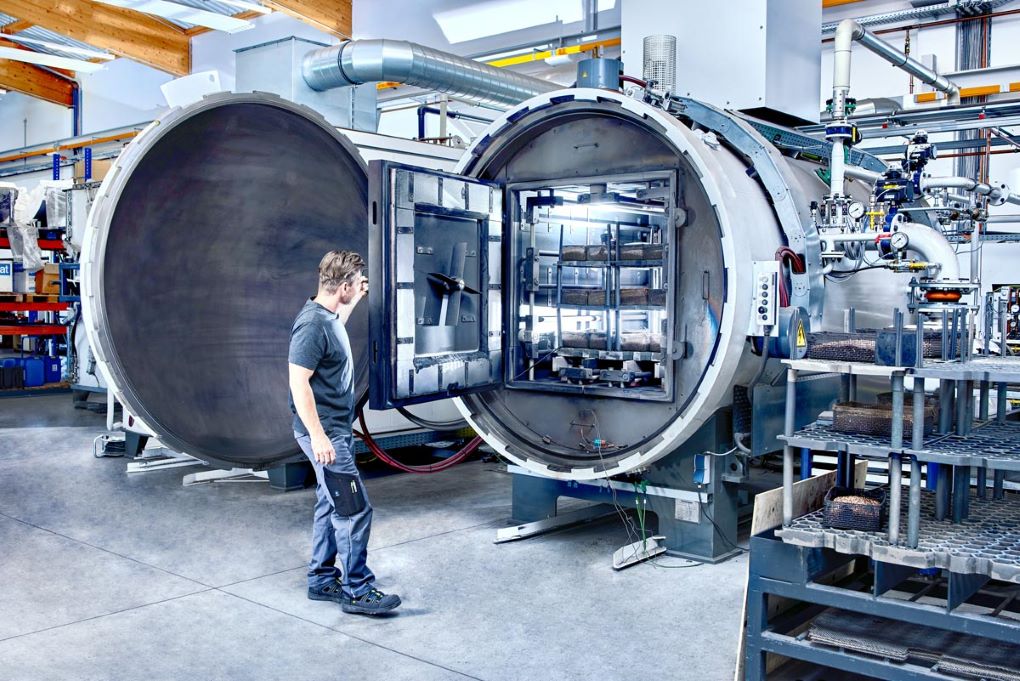

Nitriding & vacuum hardening

The extruder screws are nitrided to achieve the desired component properties.

Nitriding gives the components improved corrosion protection as well as high wear and vibration resistance. Nitriding is the only hardening process in which there is no process-related distortion of the component. No post-processing is required. The screens, which are later used in Erema systems worldwide, are vacuum hardened. During vakuum hardening, the component is heated in a vacuum and then quenched using pressurised nitrogen. The result is a bright metallic surface. The results are highly reproducible thanks to precise process control.

Further topics

Toolmaking &mechanical engineering

Punching and forming technology

Mould making

Processing machines