TOOLMAKING & MECHANICAL ENGINEERING

Mould making

HTR gives metal moulds precisely defined properties during hardening, making them particularly robust and wear-resistant for use in mould and tool making.

Further topics from toolmaking & mechanical engineering:

Stamping and forming technology | Environment/Recycling | Processing machines

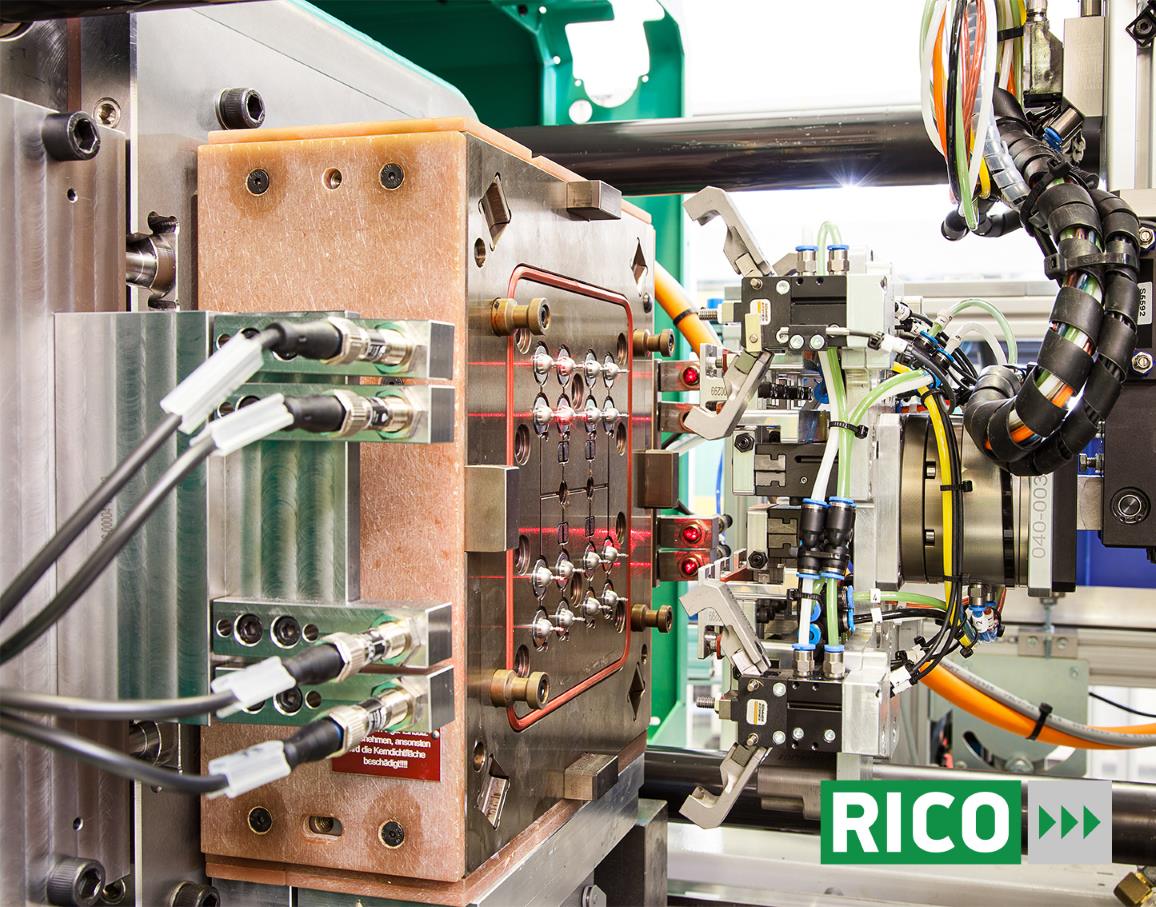

Mould making is the production of moulds that are required for the manufacture of cast parts made of metal or plastic. Steel mould making, which is closely related to toolmaking, is generally used for an end product that is produced in large quantities.

Application in toolmaking

Mould making is the production of devices that are used for the economical processing, assembly and quality control of workpieces.

Customers for mould and tool making are metal, plastics processing or foundry companies, as well as end users in various branches of industry. HTR hardens these moulds and tools in a vacuum so that they do not react with gases in the furnace and retain their bright surface. This proven process has become indispensable in a modern hardening shop.

The seamless core temperature measurement enables extremely precise process control and optimum, easily reproducible results.

Some moulds are nitrided in order to achieve the desired component properties. Nitriding gives the components improved corrosion protection as well as high wear and vibration resistance.

Nitriding is the only hardening process in which process-related distortion of the component can be ruled out. As the workpieces remain metallically bright during the hardening process, the effort involved in hard machining is reduced to a minimum.

Further topics

Toolmaking & mechanical engineering

Environmental technology

processing machines

Punching and forming technology