TOOLMAKING & MECHANICAL ENGINEERING

Processing machines

As a reliable partner, HTR supplies wear-resistant components with high fatigue resistance to market leaders in the mechanical engineering sector.

Further topics from mould making & mechanical engineering:

Environmental technology | Mould making | Stamping & forming technology

Mechanical engineering is a classic engineering science and ranges from the development and design to the production of machines. The core areas of mechanical engineering include production, drive and conveyor technology.

Processing machines

Mechanical engineering

HTR is a reliable partner to the world's leading mechanical engineering companies, including the Upper Austrian technology champions Linsinger and Weingärtner.

Linsinger GmbH in Steyrermühl, Upper Austria, has been demonstrating the highest level of engineering skills since 1939, while Weingärtner has specialised in the manufacture of special machine tools for over five decades and offers the most economical process for the production of complex extrusion and injection moulding screws

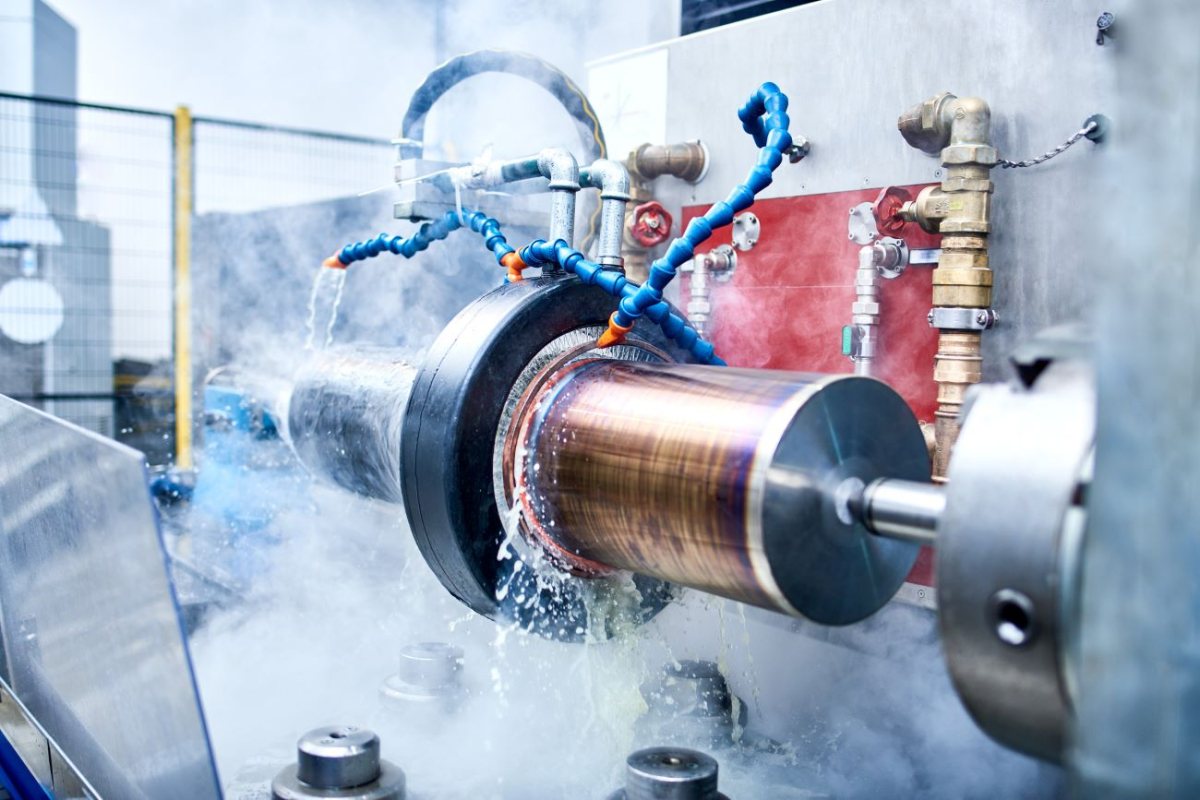

The hardening processes for components

HTR supplies hardened milling cutter holders and drive spindles, among other things, for the pioneers of mechanical engineering.

These are nitrided or induction hardened. In induction hardening, the areas to be hardened are heated using induction current and then quenched using a water spray if required. The entire process is customised to a single component so that even components with complex geometries can be hardened. The result is components with high fatigue resistance and improved wear resistance.

Further topics

Tooling & mechanical engineering

Environmental technology

Mould making

Punching & forming technology